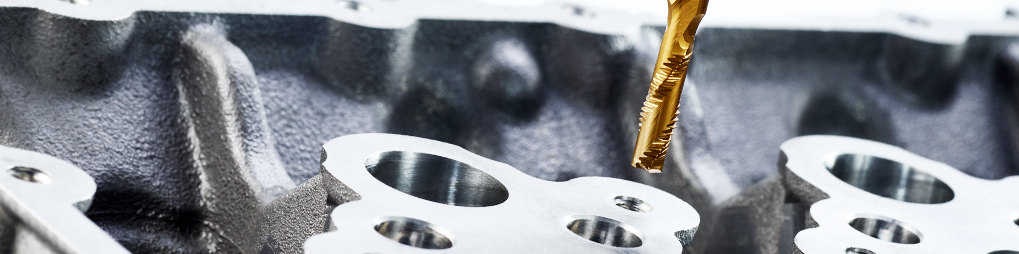

Thread with maximum confidence, depth, versatility and economy. Emuge offers an array of carbide thread milling solutions like the SHUR-THREAD™ full thread profile carbide tread mills, THREADS-ALL™ miniature size thread mills or GIGANT-IC indexable insert thread mills for large diameter threads.

THREAD MILLING TECHNOLOGY ADVANTAGES

• Produce threads with excellent form, finish, and dimensional accuracy

• Easy machining of difficult materials

• Eliminate the possibilities and consequences of tap breakage

• Achieve full-bottom threading and precise thread depth control

• Optimum positional accuracy

• Pitch diameter can be controlled by CNC offset

• One tool for right-hand and left-hand threads

• One tool for through or blind holes

• Produces small controllable chips (no bird nesting of chips)

• Less cutting pressure for thin walled parts

Emuge offers a wide range of solutions tailored to meet your specific needs.

But what really separates Emuge from all other thread mill manufacturers is customer support. Emuge support technicians will make the proper tool selections on request and then supply you with the proper machine codes to run the tooling at maximum efficiency. No other company can do this like Emuge.

AURA QUANTUM SAX ESTWO

DRILL AURA QUANTUM SAXDrill / Thread / Chamfer

Emuge‘s original solid carbide „Thriller“ drill, thread & chamfer thread mills combine the operations of 3 tools into one.

Solid carbide BGF Thriller style thread mills can reduce cycle time and manufacturing costs by combining the drilling, threading and chamfering process into one tool. BGF thread mills provide complete process flexibility. The drill point geometry of a BGF Thriller thread mill produces the exact thread hole size. Thread milling allows for in-process thread profile programming adjustments while a combined chamfering feature provides concentric location and full control of chamfer depths. Tool costs can be reduced by combining operations and the cost of part repairs from broken taps is eliminated.

AURA QUANTUM SAX ESTWO

DRILL AURA QUANTUM SAXFull Profile Thread Mills / SHUR-THREAD™ – Solid carbide full profile thread mills

Emuge SHUR-THREAD™ GF solid carbide thread mills are manufactured to the most exacting tolerances to provide maximum tool performance and part quality. The full profile thread design is the most stable form of thread milling and can reduce cycle times when compared to single point tooling. Thread milling provides the highest level of threading process security, which is especially important in high value parts where tap breakage is a possible issue. GF thread mills are available in a wide range of options, solid and coolant fed which provides the maximum amount of flexibility when developing an efficient manufacturing process. GF-Z and GF-Vario-Z have an increased number of flutes and higher core diameter for added rigidity and stability in the cut. You are sure to find the right tool for your application with SHUR-THREAD thread mills.

AURA QUANTUM SAX ESTWO

DRILL AURA QUANTUM SAXFull Profile Thread Mills / Solid carbide full profile thread mills for pipe threads

Emuge GF solid carbide thread mills are manufactured to the most exacting tolerances to provide maximum tool performance and part quality. The full profile thread design is the most stable form of thread milling and can reduce cycle times when compared to single point tooling.

Thread milling provides the highest level of threading process security, which is especially important in high value parts where tap breakage is a possible issue. GF thread mills are available in a wide range of options, solid and coolant fed which allows for the maximum amount of flexibility when developing an efficient manufacturing process.