Over 100 Years of Precision Milling and Innovation

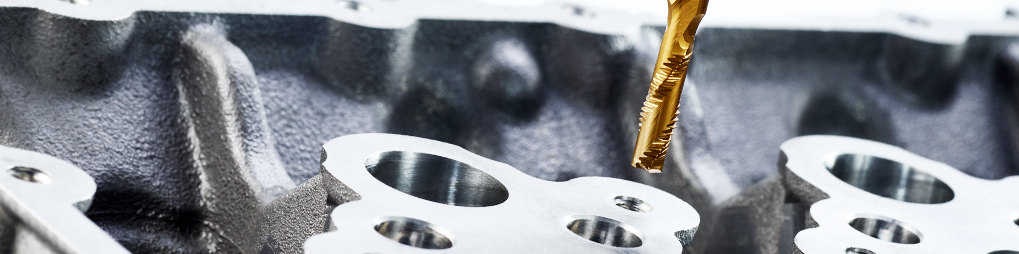

Our high precision tools are specifically designed for optimum performance in a wide range of materials and machining applications. Emuge not only produces tools, but we offer milling solutions with on staff milling specialist who can assist with developing innovative programming strategies that maximize the performance of the cutting tools. We work closely with today‘s leading CAM software companies and offer on-staff milling specialist and field technical represenatives to help guide you through the process of optimizing the milling process. Our goal is to provide only the highest quality milling products that meet only the highest performance level expectations.

The EMUGE-FRANKEN Company

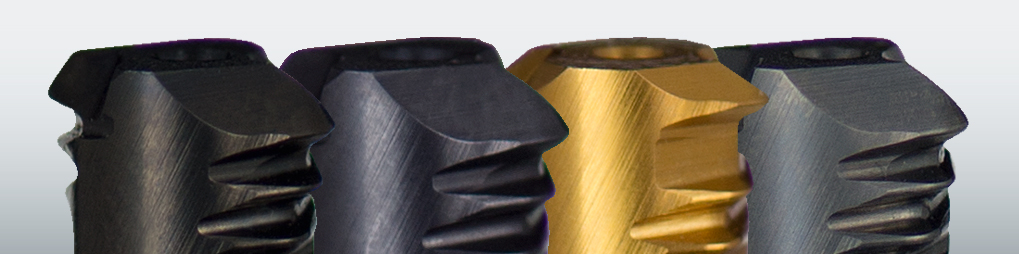

Ever since its foundation, FRANKEN, as part of the EMUGE-FRANKEN company, has been developing and manufacturing high precision milling tools-a wide range of solid carbide end mills, along with PCD, CBN and Diamond coated end mills, indexable milling cutters, inserts, and specialized milling cutters- all characterized by precision and innovation. The Franken production facility is located in Rückersdorf, Germany, and is dedicated to the manufacturing of high precision end mills and indexable cutters as well as special design form and profile milling tools. With an extensive variety of tools in a wide range of materials, Emuge-Franken provides only the highest quality cutting tools for discerning customers.